Starpery Weight Reduction 4.0 Released

In August 2021, Starpery shared the whole weight reduction tech development journey—— How to upgrade and improve the Weight Reduction Tech from 1.0 to 3.0. in TDF (thread link: https://dollforum.com/forum/viewtopic.php?t=144495)and officially started W.R. 3.0 Production. We are thrilled that more and more doll lovers started to pay attention to the light weight doll, and we can deeply receive the trust and support from those comments! For those ideas, suggestions and feedbacks from our fans, we are so appreciated!

Today, Starpery here to announce the official release of the Weight Reduction 4.0 and we want to share with you —— From Weight Reduction 3.0 to Weight Reduction 4.0, how far have we come?

After W.R. 3.0 was officially put into mass production, we found there are some problems in achieving W.R. standardization: sometimes the dolls are a bit stiff while sometimes are too heavy, the weight reduction effect is unstable. So our team did a lot of research and testing right away, and found:

If we choose the softer W.R. foam core, the much heavier silicone/TPE materials (weighs up to 25kg) will severely squeeze the foam core when pouring, which caused the foam core to harden and made the weight loss poorer…

If we choose the harder W.R. foam core, the doll will be much lighter but with a poorer softness…

How to better control and balance this two aspects? This contradiction has always haunted W.R. 3.0…Therefore, we determined to find a better way to resolve it!

*************************************************************************************************************************

In previous research and testing, we came to a conclusion: it is necessary to reduce the extrusion of the TPE/silicone material on the W.R. inner core during the pouring production. But, how can this be achieved?

At the beginning of 2022, Starpery W.R. Team was set, independent of our factory, we started R&D testing in a small room.

Our team tried various methods:

Method 1:

Keep the doll mold lying flat then pour the materials to reduce the gravity effects of TPE/silicone on the W.R. inner core…

Method 2:

Use the special spindle frame to fix the doll mold for rotary pouring, then injected the foam inside the mold… (Since the picture was lost, we only found a similar picture of the spindle frame on the Internet, as shown below)

Method 3: Try the drip irrigation method to pour the material into the mold…

Until the Nth method, we still didn't find a better, more effective and more standardized method to achieve it. Then our team fell into suspicion and even thought that achieving effective weight reduce and the great softness was an irreconcilable contradiction in itself. After taking such lots of time and cost in R&D, should we continue? Persuaded by our company's leaders, W.R. team chooses to persevere! At that time, we came up with an idea: How about separating the mold and pouring silicone/TPE below the body first, then pour the rest before they solidified.

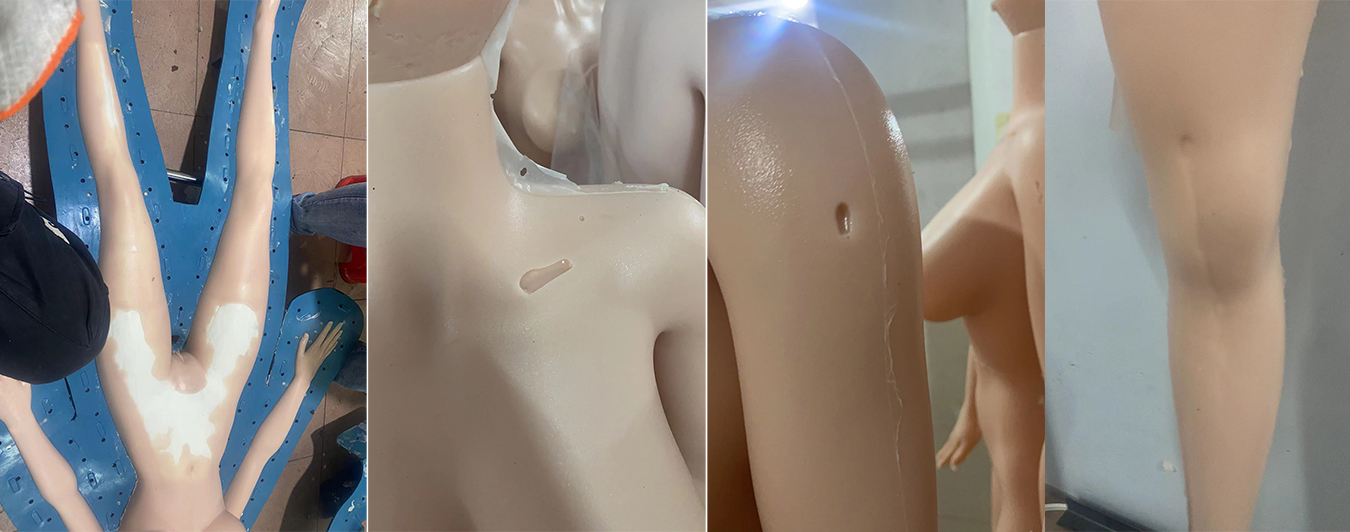

Therefore, we selected 172 body for the First Silicone mold redesign. After the new mold is done, we got the first test doll, althought it is much softer and lighter, there are more molding lines on the body, also some parts of the body are prone to lack of material, as pictures shown:

When we saw the light at the end of tunnel, more problems arose... Have taken more than half a year, it seems that we returned back to the original point, makes us so frustrated…

So our team held a meeting to summarize work in the past six months and got some useful tips:

a. The non-woven fabrics we used all the way will increase the hardness of the foam core, we need to find a way to remove it, and make the foam core directly attach to the silicone.

b. Use the drip irrigation method to pour the material into the mold, although it is slow, it helps a lot to slow down the compression of the material on the inner core.

c. The material pouring method changes, adopt the horizontal mold pouring first, then vertical pouring.

At the beginning of 2023, we started to use the new method -- By improving the foam core mold, reducing the errors between the skeleton and the inner core, and the situations of uneven skin, body lacking of material. Additionally, control the thickness of the doll's skin by controlling the thickness of the foam core.

The doll skeleton + foam core + doll mold are integrated into one piece!

Through above improvements, we finally made a better 172 body which is about 5.3kg lighter than the W.R. 3.0 body and with a more realistic softness.

Although we got a relatively satisfactory result in testing, more problems may arise when it comes to mass production. High defective rate has always been a big problem for super weight loss. Also, to make dolls better, we need to minimize the mold line, so we modified the mold again——Recast the mold to the previous design but add openings at the hand and foot areas, which is not only used to fix the doll skeleton but also can make it easier to make hard hands and feet in the future.

On the other hand, further reducing the foam core’s thickness, and allow a certain amount of silicone material pressure on it to achieve a better result. We also purchased a high cost new machine to assist in standardizing production.

In July 2023, we tested 172 and 151 two dolls many times. With W.R.4.0, this two dolls are much lighter:

172 body weight can be reduced from 35+kg (W.R. 3.0) to 29kg,

151 body's weight can be reduced from 25kg (W.R. 3.0) to about 19kg.

Moreover, we use a new better soft silicone material for production, so W.R. 4.0 doll is soft from the inside out——not only soft on the doll surface, but also inner soft, even softer than normal TPE doll.

In October 2023, we completed multiple pouring tests of these 2 dolls, basically confirmed the effect. Then we started the toughness tests until now.

Along the way, we have maintained a mentality of continuous development to create products and update technology. The development of W.R. 4.0 also made us more convinced that 600+ days and nights of hard work are worth it, we can solve the contradiction between softness and light-weight. All dear doll lovers who care about dead weights are no longer being hassled.

Thanks for the patient waiting, in the first phase, there are only 172 and 151 two bodies available for W.R. 4.0 silicone doll production. Additionally, all features are still available: Gel breasts, Fixed/Removeable Vagina, Soft butt, Hard feet, Moaning Function, Heating Function, Auto Clamping&Suction (151 W.R. 4.0 is available) Standing feet& Shrugged Shoulder, Realistic Body Painting, Matte Effect.

W.R. 4.0 will be applied to all Starpery bodies, but we still need more time to make new molds for other bodies. Please continue Staying Stuned!!

Any questions free to contact us info@starpery.com or join in our discord community: https://discord.gg/yU4NET86